S&B Technical Products, manufactures for many different specifications worldwide.

If you don’t find what you need contact us for a custom design to meet your needs.

Specialty Elastomer Gaskets for Ductile Iron Pipe & Fitting Applications

Maloney Technical Products specializes in manufacturing special elastomer pipe gaskets for water, wastewater and industrial applications. Maloney has been making products, including pipe gaskets, for over 80 years. Maloney maintains inventory of commonly used sizes as well as stocks of raw compound to quickly produce other sizes as needed.

Compounds include:

- EPDM (sulphur cured, peroxide cured available for high temp requirements)

- Nitrile

- Neoprene

- FKM (Viton® fluoroelastomer)

Other compounds are available, contact S&B.

Large Diameters and Metric sizes available on most gaskets.

S&B can supply your special elastomer gasket needs for:

- Mechanical Joint Gaskets (2″ – 42″)

- Mechanical Joint Transitions (4″ – 16″)

- Push-on joints (Tyton®) (3″ – 64″)

- Push-on Joint Transitions (Tyton®) (4″ – 8″)

- Full Face Flange Gaskets (1/8” thick/three bulb type rings) (4″ – 36″)

- Ring Flange Gaskets (1/8” thick/three bulb type rings)(4″- 36″)

AWWA & ANSI Standards Compliant:

- ANSI/AWWA C110/A21.10

- ANSI/AWWA C115/A21.15

- ANSI/AWWA C153/A21.53

- ANSI/AWWA C111/A21.11

- ASMW/ANSI B16.1

- ASME/ANSI B16.5

- AWWA C 207

NSF ![]() available on SBR compounds.

available on SBR compounds.

We carry a large inventory of many sizes.

Mechanical Joint Gasket

SPECIAL ELASTOMERS MECHANICAL JOINT GASKET

The Mechanical Joint gasket is designed to be used in cast iron mechanical joint fittings for cast iron size pipe (ductile iron and C-900 PVC). Mechanical Joint gaskets made of SBR are usually used for water and domestic sewage service. MJ gaskets made from SBR are used for air or liquid temperatures up to 150°F. For applications with temperatures above 150°F, or for other special service applications, consult the table below or call your S&B Technical Products Customer Service Representative.

Available in the following compounds:

200°F150°F

Fresh water, salt water, sanitary sewage, storm water, greases

| COMPOUNDS: | MAX SERVICE TEMPERATURE: | COMMON USES: | |||

| Water & Sewer | Air | ||||

| EPDM | 212°F | 150°F | Vegetable Oil, Alcohols, Dilute Acids, Diluted Alkalis, MEK, Acetone, fresh water, sea water, storm water, sanitary sewage & reclaimed water |

||

| Nitrile | 150°F | 125°F | Fresh water, salt water, sanitary sewage, storm water, petroleum products, oils, fats, chemicals, greases | ||

| Neoprene | |||||

| FKM | 212°F | 300°F | Fresh water, salt water, storm water, aromatic hydrocarbons, fuels, acids, vegetable oils, petroleum products, and most chemicals and solvents | ||

- Sizes 4″-24″

- Standard SBR made per ANSI/AWWA C111/A-21.11

- Rated for a water working pressure of the pipe.

Call S&B Technical Product Customer Service Representative with the project specifications for recommendation on best compound to use for a special application, current lead times and for pricing. S&B maintains inventory on many of the sizes and special compounds.

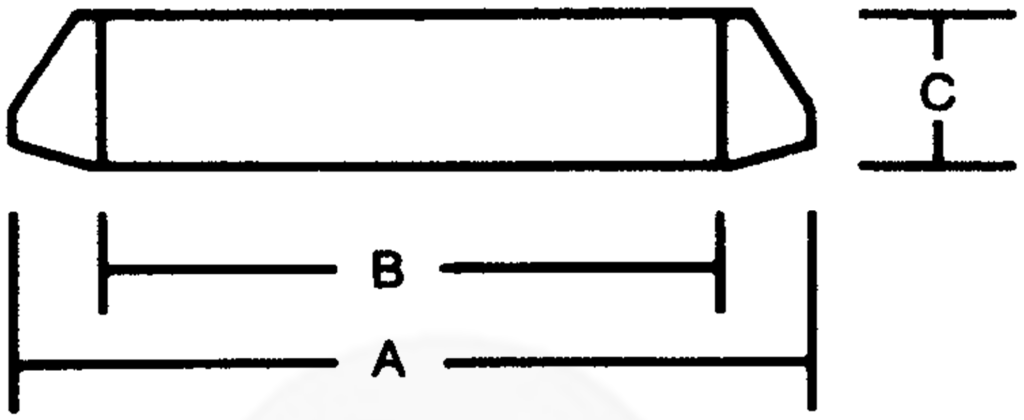

SPECIAL ELASTOMERS MECHANICAL JOINT X IPS TRANSITION GASKET

The MJ X IPS Transition gasket is designed to be used in cast iron mechanical joint fittings for adapting to PVC or steel pipe (IPS dimensions). These gaskets made of SBR are usually used for water and domestic sewage service. MJ X IPS Transition gaskets made from SBR are used for air or liquid temperatures up to 150°F. For applications with temperatures above 150°F, or for other special service applications, consult the table below or call your S&B Technical Products Customer Service Representative.

Available in the following compounds:

| COMPOUNDS: | MAX SERVICE TEMPERATURE: | COMMON USES: | |||

| Water & Sewer | Air | ||||

| EPDM | 212°F | 150°F | Vegetable Oil, Alcohols, Dilute Acids, Diluted Alkalis, MEK, Acetone, fresh water, sea water, storm water, sanitary sewage & reclaimed water |

||

| Nitrile | 150°F | 125°F | Fresh water, salt water, sanitary sewage, storm water, petroleum products, oils, fats, chemicals, greases | ||

| Neoprene | 200°F | 150°F | Fresh water, salt water, sanitary sewage, storm water, greases | ||

| FKM | 212°F | 300°F | Fresh water, salt water, storm water, aromatic hydrocarbons, fuels, acids, vegetable oils, petroleum products, and most chemicals and solvents | ||

- Sizes 4″-16″

- Standard SBR made per ANSI/AWWA C111/A-21.11

- When properly installed these gaskets can be used at working pressures up to 350 psi or the pressure rating of the pipe, whichever is less.

DIMENSIONS FOR MJ X IPS TRANSITION GASKETS

| Size | A | B | C |

| 4″ | 5.97 | 4.43 | 1.26 |

| 6″ | 8.05 | 6.53 | 1.25 |

| 8″ | 10.14 | 8.50 | 1.27 |

| 10″ | 12.17 | 10.59 | 1.26 |

| 12″ | 14.24 | 12.56 | 1.28 |

| 14″ | 16.16 | 13.77 | 1.20 |

| 16″ | 18.23 | 15.80 | 1.20 |

Call a S&B Technical Product Customer Service Representative with the project specifications for recommendation on best compound to use for a special application, current lead times and for pricing. S&B maintains inventory on many of the sizes and special compounds

Tyton®Push-on Gasket

Tyton® Push-on Gaskets

The TYTON® Push-On Gasket is used in the TYTON JOINT® Ductile Iron Pipe & Fittings. All TYTON® Push-On Gaskets are dual hardness gaskets made from vulcanized synthetic rubber, and meet the requirements of the National Sanitation Foundation (NSF) Standard ANSI/NSF-61. The standard rubber compound is SBR, which has a maximum service temperature rating of 150°F. For applications with temperatures above 150°F, or for other special service applications, consult the table below or call your S&B Technical Products Customer Service Representative.

Available in the following compounds:

| COMPOUNDS: | MAX SERVICE TEMPERATURE: | COMMON USES: | |||

| Water & Sewer | Air | ||||

| EPDM | 212°F | 150°F | Vegetable Oil, Alcohols, Dilute Acids, Diluted Alkalis, MEK, Acetone, fresh water, sea water, storm water, sanitary sewage & reclaimed water |

||

| Nitrile | 150°F | 125°F | Fresh water, salt water, sanitary sewage, storm water, petroleum products, oils, fats, chemicals, greases | ||

| Neoprene | 200°F | 150°F | Fresh water, salt water, sanitary sewage, storm water, greases | ||

| FKM | 212°F | 300°F | Fresh water, salt water, storm water, aromatic hydrocarbons, fuels, acids, vegetable oils, petroleum products, and most chemicals and solvents | ||

- Sizes 4″-64″

- Standard SBR made per ANSI/AWWA C111/A-21.11

Call S&B Technical Product Customer Service Representative with the project specifications for recommendation on best compound to use for a special application, current lead times and for pricing. S&B maintains inventory on many of the sizes and special compounds.

Tyton®Push-on Transition Gasket

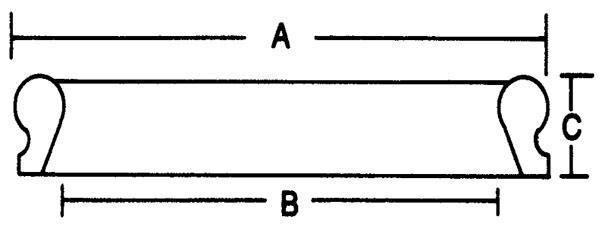

Tyton® Push-on Joint Transition Gaskets

The TYTON® Push-On Transition Gasket is designed to be used in Tyton® joint fittings for adapting to PVC or steel pipe (IPS dimensions). TYTON® Push-On Transition gaskets are dual hardness gaskets made from vulcanized synthetic rubber, and meet the requirements of the National Sanitation Foundation (NSF) Standard ANSI/NSF-61. For applications with temperatures above 150°F, or for other special service applications, consult the table below or call your S&B Technical Products Customer Service Representative.

Available in the following compounds:

| COMPOUNDS: | MAX SERVICE TEMPERATURE: | COMMON USES: | |||

| Water & Sewer | Air | ||||

| EPDM | 212°F | 150°F | Vegetable Oil, Alcohols, Dilute Acids, Diluted Alkalis, MEK, Acetone, fresh water, sea water, storm water, sanitary sewage & reclaimed water |

||

| Nitrile | 150°F | 125°F | Fresh water, salt water, sanitary sewage, storm water, petroleum products, oils, fats, chemicals, greases | ||

| Neoprene | 200°F | 150°F | Fresh water, salt water, sanitary sewage, storm water, greases | ||

| FKM | 212°F | 300°F | Fresh water, salt water, storm water, aromatic hydrocarbons, fuels, acids, vegetable oils, petroleum products, and most chemicals and solvents | ||

- Sizes 4″-8″

- Standard SBR made per ANSI/AWWA C111/A-21.11

DIMENSIONS FOR TYTON® PUSH-ON TRANSITION GASKETS

| Size | A | B | C |

| 4″ | 5.74 | 4.26 | 1.51 |

| 6″ | 7.86 | 6.38 | 1.62 |

| 8″ | 10.15 | 8.31 | 1.94 |

Call S&B Technical Product Customer Service Representative with the project specifications for recommendation on best compound to use for a special application, current lead times and for pricing. S&B maintains inventory on many of the sizes and special compound

Ring Flange Gasket

Ring Flange Gasket

S&B Technical Products recommends the use of S&B Special Elastomer Ring Flange Gasket for sealing ductile iron flanged pipe when special applications such as systems designed for transmitting oils and chemicals, high temperature water and air applications require elastomers with enhanced performance criteria above SBR gaskets.

Available in the following compounds:

| COMPOUNDS: | MAX SERVICE TEMPERATURE: | COMMON USES: | |||

| Water & Sewer | Air | ||||

| EPDM | 212°F | 150°F | Vegetable Oil, Alcohols, Dilute Acids, Diluted Alkalis, MEK, Acetone, fresh water, sea water, storm water, sanitary sewage & reclaimed water |

||

| Nitrile | 150°F | 125°F | Fresh water, salt water, sanitary sewage, storm water, petroleum products, oils, fats, chemicals, greases | ||

| Neoprene | 200°F | 150°F | Fresh water, salt water, sanitary sewage, storm water, greases | ||

| FKM | 212°F | 300°F | Fresh water, salt water, storm water, aromatic hydrocarbons, fuels, acids, vegetable oils, petroleum products, and most chemicals and solvents | ||

- Sizes 4” – 36”, 1/8” Nominal Thickness

- Rated for a water working pressure of 350psi For 4”-24” and 250psi for 30”-36”

- Compatible with flanges confirming to ANSI/AWWA C-115/A21.15, ANSI/AWWA C110/A21.10, ASME B16.1 class 125, ANSI/AWWA C207 class B, D, E and F, and ANSIB16.5 in sizes 4”-24”

- Designed for unique surface of Ductile Iron Flange joints

- Employs three ring type pieces molded into the gasket that project beyond both sides of the main surface of the gasket to greatly improve sealing and reduces bolt torque required to seal the joint

TECHNICAL DATA S&B SPECIAL ELASTOMERS RING FLANGE GASKET

| Size | OD | Working | Bolt Torque at 250psi |

Working | Bolt Torque at 350psi |

| Inches | Inches | Pressure | ft./lb | Pressure | ft./lb |

| 4 | 6.88 | 250 | 90 | 350 | 110 |

| 6 | 8.75 | 250 | 90 | 350 | 110 |

| 8 | 11.00 | 250 | 90 | 350 | 110 |

| 10 | 13.38 | 250 | 90 | 350 | 130 |

| 12 | 16.13 | 250 | 90 | 350 | 130 |

| 14 | 17.75 | 250 | 110 | 350 | 150 |

| 16 | 20.25 | 250 | 110 | 350 | 160 |

| 18 | 21.63 | 250 | 120 | 350 | 180 |

| 20 | 23.88 | 250 | 120 | 350 | 200 |

| 24 | 28.25 | 250 | 130 | 350 | 220 |

| 30 | 34.75 | 250 | 140 | 350 | – |

| 36 | 41.25 | 250 | 160 | 350 | – |

Prior to assembly, make sure the flanges are free of sand, grit, grease or other foreign material.

Hand tighten all bolts and check for alignment. Use a crisscross pattern to tighten the bolts, starting with the top bolt then the bottom bolt 180° from the top bolt, then 90° to the left and tighten that bolt, then 180° to the right across from it then one bolt to the right and repeat the crisscrossing for the remainder of the bolts. Flange bolts must be evenly torqued in stages to provide proper sealing.

These gaskets were designed specifically for the unique surface of Ductile Iron. Flat rubber gaskets are NOT considered equal in performance and may not provide the sealing capability the project requires. In addition, their use could result in unintended damage to the flanges and threads of the fabricated pipe by applying excess torque to the bolts/flanges in order to seal.

Call S&B Technical Product Customer Service Representative with the project specifications for recommendation on best compound to use for a special application, current lead times and for pricing. S&B maintains inventory on many of the sizes and special compounds.

Full Faced Style Gasket

Full Face Flange Gasket

S&B Technical Products recommends the use of Special Elastomer for sealing ductile iron flanged piping for special applications such as systems designed for transmitting oils, chemicals, high temperature water and air applications. These conditions require elastomers with enhanced performance above those provided by standard SBR gaskets.

Available in the following compounds:

| COMPOUNDS: | MAX SERVICE TEMPERATURE: | COMMON USES: | |||

| Water & Sewer | Air | ||||

| EPDM | 212°F | 150°F | Vegetable Oil, Alcohols, Dilute Acids, Diluted Alkalis, MEK, Acetone, fresh water, sea water, storm water, sanitary sewage & reclaimed water |

||

| Nitrile | 150°F | 125°F | Fresh water, salt water, sanitary sewage, storm water, petroleum products, oils, fats, chemicals, greases | ||

| Neoprene | 200°F | 150°F | Fresh water, salt water, sanitary sewage, storm water, greases | ||

| FKM | 212°F | 300°F | Fresh water, salt water, storm water, aromatic hydrocarbons, fuels, acids, vegetable oils, petroleum products, and most chemicals and solvents | ||

- Sizes 4” – 36”, 1/8” Nominal Thickness

- Rated for a water working pressure of 350psi For 4”-24” and 250psi for 30”-36” and are based on maximum rating of C110, C111 & C153 flange

- Holes match ANSI A-21.10, A21.15 and B 16.1 Class 125 Flange drilling.

- Designed for unique surface of Ductile Iron Flange joints

- Employs three ring type pieces mold into the gasket that project beyond both sides of the main surface of the Gasket to greatly improve sealing and reduces bolt torque required to seal the joint

TECHNICAL DATA S&B SPECIAL ELASTOMERS FULL FACE FLANGE GASKET

| Size | BC | Pressure | Number |

Working Pressure / Bolt |

|

| Inches | Inches | Rating | Bolt Holes |

at 250 PSI |

at 350 PSI |

| 4 | 7.50 | 350psi | 8 | 90 | 110 |

| 6 | 9.50 | 350psi | 8 | 90 | 110 |

| 8 | 11.75 | 350psi | 8 | 90 | 110 |

| 10 | 14.25 | 350psi | 12 | 90 | 130 |

| 12 | 17.00 | 350psi | 12 | 90 | 130 |

| 14 | 18.75 | 350psi | 12 | 110 | 150 |

| 16 | 21.25 | 350psi | 16 | 110 | 160 |

| 18 | 22.75 | 350psi | 16 | 120 | 180 |

| 20 | 25.00 | 350psi | 20 | 120 | 200 |

| 24 | 29.50 | 350psi | 20 | 130 | 220 |

| 30 | 36.00 | 250psi | 28 | 140 | – |

| 36 | 42.75 | 250psi | 32 | 160 | – |

Bolt holes match ANSI A21.10, A21.15 AND B16.1. All gaskets meet the requirements shown in the appendices of AWWA C110, C111 and C115.

Prior to assembly, make sure the flanges are free of sand, grit, grease or other foreign material.

Hand tighten all bolts and check for alignment. Use a crisscross pattern to tighten the bolts, starting with the top bolt then the bottom bolt 180° from the top bolt, then 90° to the left and tighten that bolt, then 180° to the right across form it then one bolt to the right and repeat the crisscrossing for the remainder of the bolts. Flange bolts must be evenly torqued in stages to provide proper sealing.

These gaskets were designed specifically for the unique surface of Ductile Iron. Flat rubber gaskets are NOT considered equal in performance and may not provide the sealing capability the project requires. In addition, their use could result in unintended damage to the flanges and threads of the fabricated pipe by applying excess torque to the bolts/flanges in order to seal.

Call S&B Technical Product Customer Service Representative with the project specifications for recommendation on best compound to use for a special application, current lead times and for pricing. S&B maintains inventory on many of the sizes and special compounds.

ISO 2531

Size:

Mechanical Joint

ANSI/AWW C111

Push On/Tyton

ANSI/AWWA C111, C151, C153

Size:

Push On/Tyton Metric

ISO 2531

Size:

AS/NZS 2280

Size: