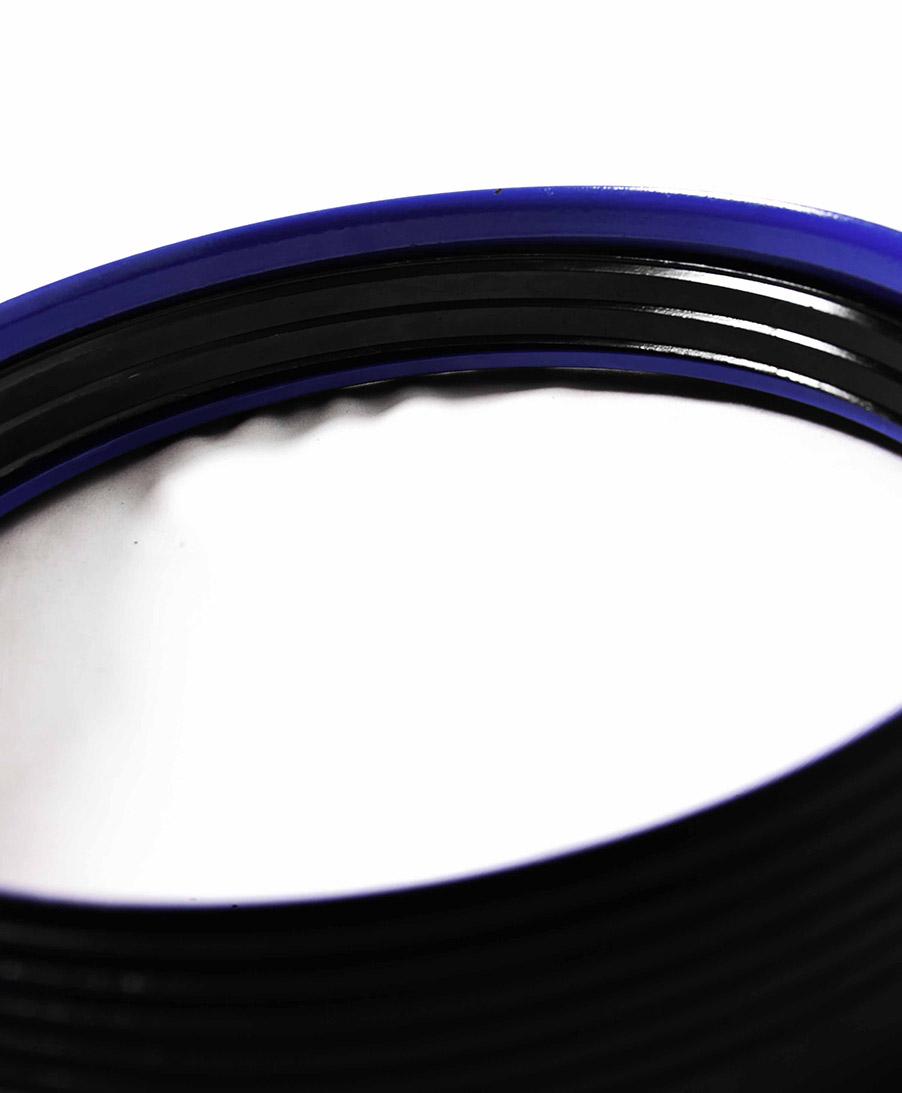

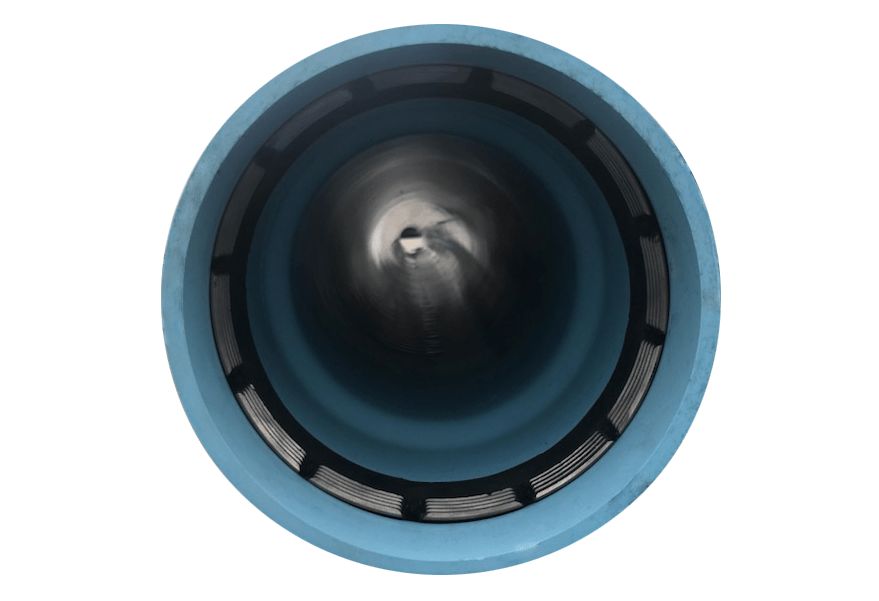

Manufacturing: The Bulldog™ restraint system is installed during the PVC pipe belling process, along with the Rieber C-900 gasket.

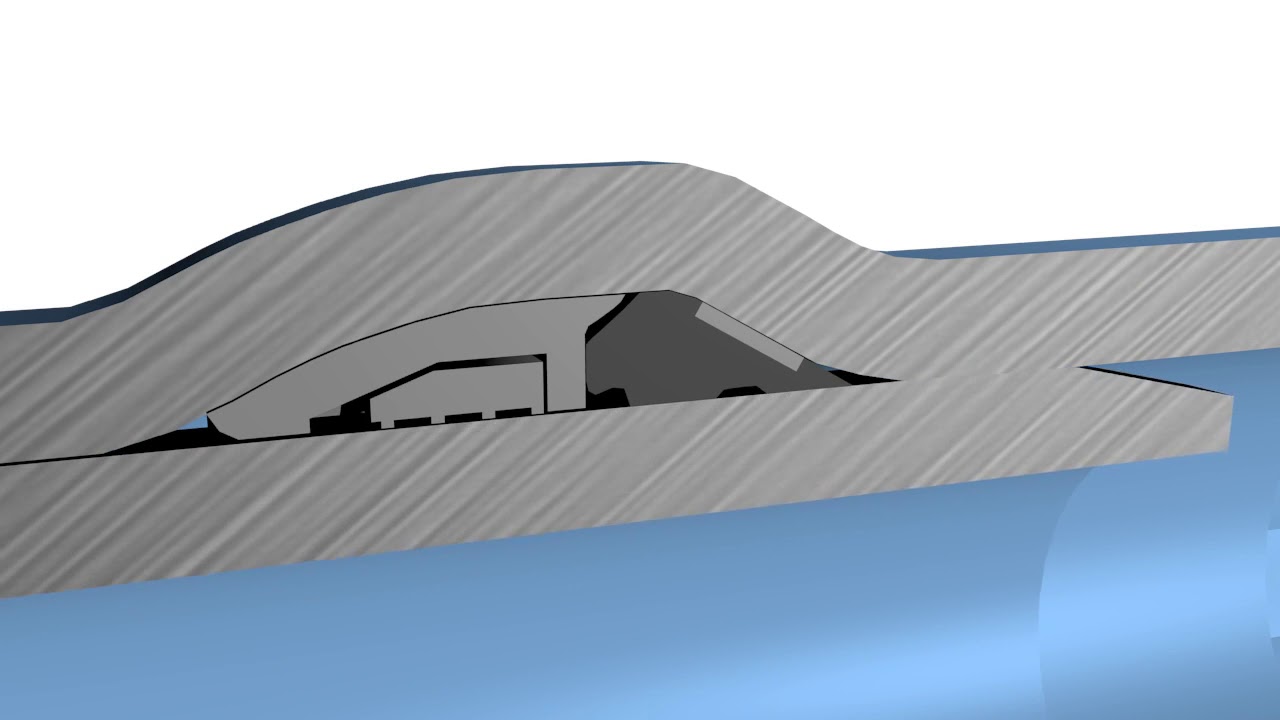

No Point Loading: In non-serrated type restraint systems, the manual tightening of restraining wedges into the walls of PVC pipes commonly causes point-loading on the pipe wall, jeopardizing the pipe’s hydrostatic strength. This leads to potential problems in the long-term operation of the pipeline. The BullDog™ doesn’t rely on point loading.

Easy Assembly: Assembly of the BullDog™ joint is similar to the joining of the traditional Rieber-gasket PVC pipe joint. There are no tools, external rods, clamps or bolts needed! The restraint mechanism is activated by simply pushing the spigot into the bell of the adjoining pipe equipped with the BullDog™ and then pulling it to set the joint.

Less Potential for Human Error: The easy assembly method also lessens the opportunities of human errors involved in the installation of external joint restraint devices. There are no nuts and bolts to tighten and there are no correct torques to worry about.

No Corrosion: The minimal exposure of the BullDog™ joint restraint to the elements makes it significantly less prone to corrosion than external joint restraint devices. There are no rods and harnesses to corrode! The gripper ring and the ring casing are coated with a patented coating system.

All-in-One Restraint and Sealing Solution for Anger Type Joints

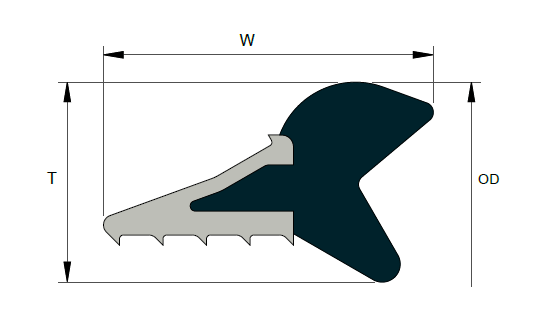

Twelve metal segments engineered to deliver the right balance between gripping and ease of installation provide thrust restraint without requiring thrust blocks, resulting in savings of material and labor thanks to reduced components and assembly time.

Material Information

- SBR synthetic rubber compound

- Rubber hardness: 55±5 Shore A

- EPDM and NBR synthetic rubber compounds

- Metal inserts made of stainless steel

Special Features

- Suitable for bell-end PVC U, O, M, I and A pipes for making joints under AWWA C900 & C909

Standards Compliance

- ASTM D3139 in combination with a compliant pipe

- ASTM F477 requirements for High-Head application (HH)

- NSF 61/NSF 14/ANSI/CSA B137

Joint Requirements

- Applying water is recommended to facilitate seal installation

- Pipe joints shall conform to applicable industry

- Spigot end must be chamfered with a 15° angle and edges should be rounded to ensure a proper joint

- Lubricant is required for joint

Quality Assurance

- Quality system: ISO 9001:2015

- Rubber laboratory accreditation: ISO/IEC 17025:2005

Marking and Labels

May include, but not limited to:

- Product name

- Size & sizing standard

- Date and place of manufacturing

- Material designation

- Patent information

Testing

- The joint assembly shall be tested according to ASTM D3139 and

Basic Dimensions

* Other sizes can be developed upon request |

||||||||||||||||||||||||||||